I-TRIZ: The Next Big Thing?

The I-TRIZ method for promoting technological innovation and Inventive Engineering

Published in Hebrew in

Status - Management

Thinking Magazine August 1998

By Dr. Yoni Mizrachi, Organizational and Strategic Consultant,

ZOOZ

Part II

Details: Principles and Applications

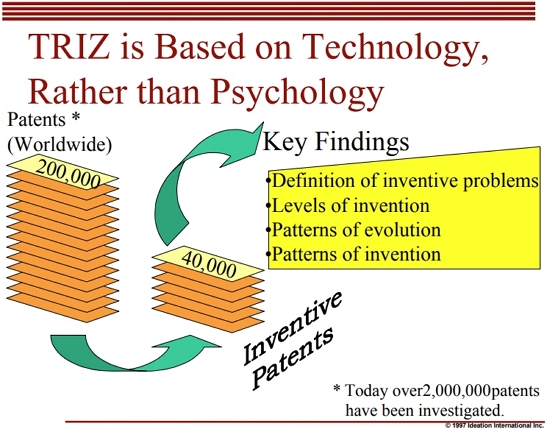

What is it in the method that allows anyone who has learned it and applies it properly to become a solver of technological problems? What does the method have that allows people with a ‘natural’ bent for invention to become far more productive and efficient technological innovators? To answer these questions let us first turn to the matter of how the human brain works. One of the most striking analogies for describing the thinking process of the human brain is to see it as a barren wilderness stretching as far as the eye can see, scarred with gashed channels of dried-up riverbeds. The raindrops that fall on this desert always drain into channels lower than the surface and are carried in them to the central channel, and thence to the drainage basin. The raindrops are like the information, the stimuli, and the experiences picked up by our brain from the environment. The river channels are analogies to the knowledge, experiences, paradigms, and earlier axioms that a person has experienced. As the previous rains dug deeper into the thinking channels, so does the rigidity of thinking that a person may suffer from become deeper and more firmly fixed. Furthermore, as a person’s area of professional expertise grows more profound, and as the level of his or her professional education in other fields sinks, (as a function of times of specialization and experience), so does the likelihood of his or her being able to see what lies beyond the walls of the thinking channel in which he or she is trapped decrease. This comprehension of how the human brain thinks is not new. In the 1960s scholars in psychology and creative thinking wrote about it. The foremost and most vocal of them was probably Edward de Bono, whose techniques of lateral thinking were directed precisely to solving the problem depicted here: how to free the human brain from thinking in fixed patterns and channels, and to lead it to lateral thinking beyond the thought channels.

The I-TRIZ innovation path provides a context in which brainware interacts with software, thereby leading to creative synergy. In essence, I-TRIZ may be seen as a way of thinking and methodical analysis intended to overcome the thinking rigidity by application of systematic principles of thinking for analysis and solution of problems, with emphasis on the engineering and technological domains. A problem-solver who uses the theory and its methodological tools dons a kind of pair of glasses that allow him a unique way of observing problems: a way intended to free the observer from psychological and professional fixations and preconceptions that restrict his or her ways of analyzing reality. The way of thinking and seeing reality by means of TRIZ encourages and almost forces on the human brain creative thinking outside specialist channels and earlier paradigms. Compared with the usual methods, TRIZ does this through transferring scientific and technological knowledge across areas by means of analogical thinking. Exiting the regular thought channels is not done by general creative brainstorming but by the systematic examination of thousands of relevant applied analogies from variegated fields of science and technology. The development from the 1990s of highly powerful computerized support tools, which include programs for defining and visual mapping of problems, alongside knowledge bases allowing easy, guided, and intuitive access to an enormous body of theoretical knowledge with over fifty years of thinking, make the I-TRIZ method a unique feature of the theoretical and applied landscape, in connection with modern managerial and organizational sciences.

The R&D person who puts on the I-TRIZ ‘glasses’ and uses its software tools and its knowledge bases analyzes the problems (problems of development and amelioration of an existing system, problems and snags present in an existing system, problems connected with planning a new system from zero) in a special way, so in most cases he or she has a higher potential for identifying original and optimal solutions. What do the lenses of the TRIZ ‘glasses’ consist of?

To answer this question, we’ll take problems from various fields and see how the TRIZ lenses are applied and how they work. For demonstration purposes, we show only three principal ‘lenses’ and the approaches to solutions deriving from them.

Lens 1 – Principle of Ideality

Thinking components, methodology, and software (knowledge bases) that lead the observer to bring a system to its ideal state. Problem: In a large poultry farm for egg production a conveyor belt carries the eggs from the laying house to the packing area. In the packing area an automatic arm lifts each egg off the belt and places it on the machine that stamps the production date, and then the arm transfers the egg to the container. The farm managers want to improve the process in terms of time, cost, and complexity. TRIZ thinking about the problems from the Ideality perspective: Problem solvers trained in the method and using its tools study the problem from the viewpoint that emphasizes a total solution to the problem and which avoids as far as possible offering solutions emphasizing local cumulative improvement. The assumption of the method is that the best system is one that performs its intended function at minimum (or without) existence of the system. Such a concept leads the problem solvers to identify the optimal and minimal solutions for achieving the desired action. Systems planned by the TRIZ concept will therefore use fewer resources, include fewer components, and their level of complexity (as well as the number of things that co go wrong…) is expected to be optimal. TRIZ solution of the problem by the ‘principle of Ideality’: A stamp with the production date will be placed on the inner side of the egg-lifting arm, so that whenever the arm lifts an egg it stamps it with the actual stamping, and then transfers the egg directly to the container. This solution will entirely eliminate the date-stamping machine, and will in fact achieve the desired result without the existence of a designated machine (with its cost and operation cost) and using existing processes. By applying the ideality principle, engineers of Ideation International Inc. engaged on a project for a large producer of vehicle brake assemblies were able reduce the number of parts in a certain braking system from twelve to only four, thereby reducing production costs by 50 percent, simplifying production processes, and raising the general reliability level of the system. The above principle may of course be applied to any system (electronics, mechanics, chemistry, optics, software) and to combinations of subsystems in various fields (electro-optics, biotechnology, etc.).

Lens 2 – Principle of Contradictions

Thinking components, knowledge bases, and methodology leading the observer to identify and use contradictions in a system. Problem: A big car maker faces the following dilemma: to reduce the weight of the car door while preserving the lateral protection it gives passengers against impact. To improve fuel consumption, the overall weight of the car is lowered and the weight of the door (because of a massive steel rod in its forward part that serves to absorb the impact of collision) has to be reduced while its strength properties have to be maintained.

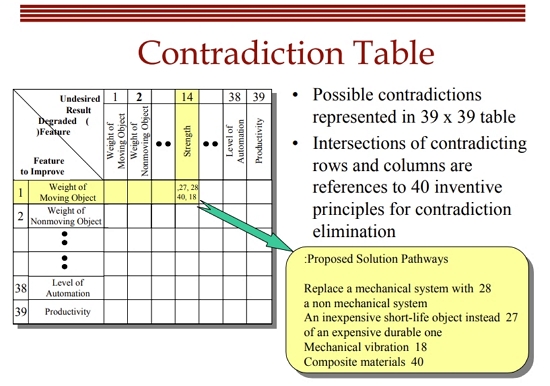

TRIZ thinking about the problem from the perspective of contradictions: The human thought pattern seeks to avoid opacity and situations of conflict and contradiction. These are therefore conceived as problematic and should be eliminated, and/or mitigated and adapted to familiar frameworks and thinking patterns. Problem solvers versed in the method and who use its tools study the problem from the viewpoint that looks for contradictions in the system and utilizes them to its advantage. Contradictions exist in every engineering/technological system. For example, the physical strengthening of certain components will require an increase in the thickness or weight and by contrast will reduce the speed and/or will enlarge the volume of the parts. Every element and/or property in a system has positive and negative qualities. Classic improvement methods in systems strengthen one component and simultaneously add some negative property arising from that very strengthening (strengthening a component by thickening, for example, will increase its weight and volume). On the basis of this thinking mode, Altshuller constructed his Contradiction Table, which examines fundamental contradictions among 39 engineering parameters (e.g., weight, strength, speed, cost, productivity), and proposed inventive solutions (arising from the study of hundreds of thousands of patents) for each of these generic contradictions. The problem solver who thus identifies a contradiction in the system (e.g., between strength and weight) can turn to the Contradiction Table (39 x 39 contradictions) and to the major inventive principles that arose from study of the patents, and chooses from a large number of solution concepts the optimal way of resolving the contradiction. The method’s advantage is that the spread of fundamental solutions offered to the solver is not limited to those in his or her area of specialization, but derives from a much wider range of ‘working’ solutions in all fields of science and technology. The TRIZ solution of the problem according to the Principle of Contradictions: Using the classic table (interactively accessible in the knowledge base), we look for the main inventive solutions for the contradiction between the engineering parameters ‘weight of moving object’ (door weight) and ‘strength’ (door’s ability to protect passengers from lateral impact). The software automatically provides us with four alternative solution tracks for the basic problem, of which we shall consider only two for the purpose of illustration. One of these fundamental solutions for the kind of contradiction presented here for discussion calls for the utilization of composite materials (plastic reinforced with carbon fibers, for example), which are lighter and stronger than steel. This is done nowadays in certain components of advanced fighter aircraft. The other fundamental solution for the given kind of contradiction supplied by the knowledge base concerns replacing fixed components in the system by alternative components that change their physical nature only when appropriate conditions are met. The analogy is replacement of the steel rod by an entirely different component that will achieve identical results to those of the steel rod only when the condition of impact is met. A possible solution according to this principle is therefore installation of airbags in the side door (as is done today in several luxury automobiles). The use of the principle of contradiction and others stored in the knowledge base allowed Ideation’s engineers working on a project for a large manufacturer of jet engines to reduce the weight of a particularly heavy engine part by over 30 percent, and thus increase the engine efficiency and decreased the energy loss of the aircraft.

Lens 3 – Utilization of Resources

Thinking components, knowledge bases, and methodology leading the observer to identify and utilize most of the existing resources in the system. Problem: Exhaust gas emissions from internal combustion engines (which use fuels) and/or from various production processes cause damage to the environment in general and to people working in vicinity of the systems in particular. New laws to protect the environment and the workers now require a significant lowering of pollution levels and the installation of expensive machinery in plants and cars to trace and control gas emissions. TRIZ thinking about the problem from the perspective of use of existing resources in the system: Problem solvers trained in the method and who use its tools scrutinize an engineering/technological system from an angle that looks for overt and/or hidden and/or derived resources present in the system, and work to harness these resources for solving problems. The assumption is that an optimal solution to problems in engineering/technological systems does not add resources to the system but exploits existing resources, even if they are hidden. For example, in systems there may be energy resources (heat emitted in the system operation processes), time resources (dead time intervals in which a sub-component of the system performs its action), material resources (waste products and/or components present in the system), and more. The combination of existing resources allows production of many secondary resources, for example, a certain waste product in a system in combination with heat resources generated by the system may create a new kind of material resource that can be utilized for coating or energy, for example. The use of existing resources in a system allows better utilization and maximization of their advantages, and also firms up connectivity among sub-systems of the super-system without adding new components to it. The TRIZ solution for the problem by the principle of ‘Resource Utilization’: The knowledge bases guide us to examples and principles indicating utilization of emission of gases in combustion engines for many positive purposes: exhaust gases from a car engine can be used to operate alarm sirens in the case of auto theft, inflate airbags as necessary (for example to help change a wheel), and more. In some cases the problem can be solved entirely, together with a direct benefit: in advanced plows harnessed to tractors, the exhaust pipe of the tractor is connected to the plow and emits the gases next to the blade under the surface. In this process some of the noxious gases are filtered through the soil (an efficient filter), the plow blade gets a coating for its protection, and the soil is enriched by organic particles. This is a particularly elegant solution to the problem of gases because it achieves both a direct solution to the problem and a series of benefits without allocation of additional energy and/or material resources to the system. This kind of solution makes possible identification of an endless range of specific gas emission problems.

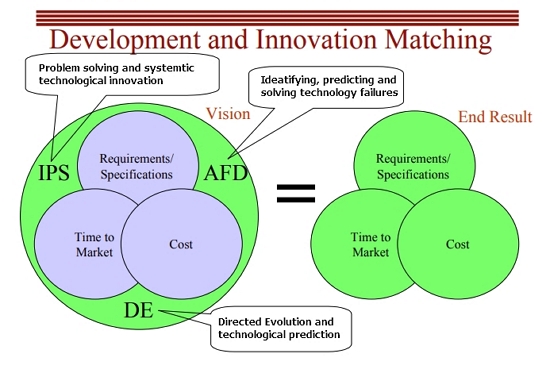

In recent years these and many other principles have been arrayed in a framework of three systematic work methodologies (intervention areas) intended to lead the user along the path to identifying the principles most relevant to his or her specific problem in the shortest time.In practice, the method and the software tools support managers, R&D teams, work teams, and support teams in the following three intervention areas, each of which is now separate (with its own theory, methodology, and software tools), but which may be operated in an integral fashion.

Inventive Problem Solving (I.P.S.) – The I.P.S. area is meant to support identification, definition, problem solving, and technological-engineering development in existing and planned systems. The problem solver who has to improve and/or plan a new system is conducted along a work path supported by software designed to allow him or her rapid and optimal detection of fundamental planning problems and their speedy solution. The software tools make it possible to formulate the various aspects of the problem and include production of flowcharts and computerized relationship systems among sub-systems, automatic production of the principal solution paths (concepts for solution), and direction to the parts of the knowledge base identified by the system as specially relevant to the application of the principal solutions. The problem solver exposed to the concepts of solution and the many illustrated examples showing earlier relevant patents used for solving similar problems to the one in hand may in most cases derive a creative analogy (solution) between the patent described in the knowledge base (which may come from any existing area of knowledge and technology) and his or her particular problem (in any existing area of knowledge and technology). The I.P.S. domain has been applied in the solution of thousands of problems, from improving truck fenders (Ford) to optimal planning of complex production lines and processes in the oil and fuel industry (AMOCO). At present, advanced experiments are being conducted on the application of these principles to the software industry.Anticipatory Failure Determination (A.F.D.) – The A.F.D. area is designed to support the location, diagnosis and anticipation of failures in existing and planned systems. The problem solver needing to identify failures in an existing system or to apply preventive anticipation (debugging) of failures in a new or planned system is guided along a software-supported work path constructed to allow him or her rapid and optimal detection of failures and their effective solution. The method user is required to engage reverse thinking: he or she becomes a ‘saboteur’ systematically testing how to wreck the system in the most efficient way. To do so, he or she uses software tools that afford him or her systematic mapping of potential causes of failure in order of importance and probability, and automatic direction to those parts of the knowledge base identified by the system as specially relevant to solving the problem. In military terms, the approach is particularly efficient and applicable for locating the ‘soft underbelly’ of weapons systems in the hands of the opponent and inflicting damage on enemy systems. Here too the fundamental failures under consideration, like the abundance of offered solutions, are inter-domain in nature, so the problem solver is not restricted to solutions within his or her area of expertise or conceptual limits of thinking. The A.F.D. field has been applied to problems such as mechanical failure in helicopter rotors, producing microwire with intermetal compositions, and many others.

Directed Evolution (D.E.) – The D.E. area is designed to support technological prediction and active direction of evolutionary development of products and systems. D.E. is considered the latest and most complex area of the method, and space is too short to go deeply into detail about it here. In principle, it is identification of the place of a given system in relation to fundamental-general development tracks of technological systems as observed by longitudinal historical studies of thousands of products and systems throughout the course of human technological history. From analysis of the existing state of a system for which technological prediction is sought regarding these evolutionary principles, it is possible to identify the developmental stage at which the system is at the moment, and to identify alternative development tracks envisaged for it. Thus the system builders can actively steer towards whichever developmental alternative they choose, and prepare drawer plans (preliminary R&D) for the subsequent stages and define new markets for new products, while establishing the game rules and business primacy on the grounds of technological superiority (via securing its intellectual capital by means of patent fences, brand-names, and prior and obligatory definition of standards). Application of principles and tools in the domain allowed I-TRIZ people to propose R&D directions and strategies of commercial development to the American Northern Telecom (Nortel) company in the area of voice recognition. Similar projects are being conducted today for the petrochemical industry and in fields of wireless communication. In the world of business, where R&D constitutes an ever-growing part of company budgets, D.E. is considered the most promising and interesting area in the method. Because of its complexity, it is only partially supported by known software means.

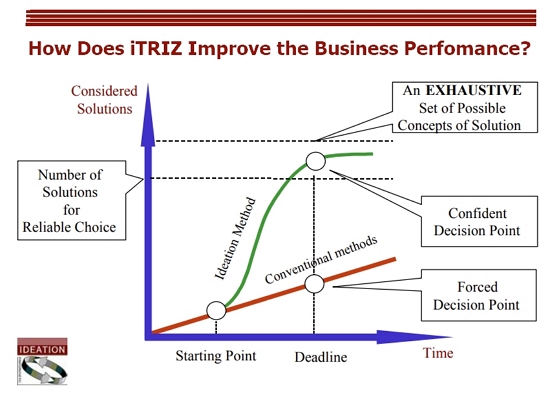

Of two competitors working in the same eco-business branch, the one that adopts the method and inculcates it correctly may expect a more impressive adaptation ability to the contemporary knowledge economy, characterized by products’ short shelf-life and encouragement of frequent technological innovation. The secret is simple, and in business terms it lies in the fact that the user of the method, its knowledge bases, and its software can gain more and richer solutions at a given point in time. The direct significance is higher potential to test and choose the best option for performance in a given time and/or to shorten the time of bringing to market a product that not only appears earlier but is also optimal from the viewpoint of production, development, and customer’s needs.

Considerations regarding adaptation to the work culture in Israel

One of the most apt comparisons known to me between the work culture of the Israeli technical person and his or her American counterpart relates to the different way in which the two deal with a new machine and/or technology. The American carefully undoes the packaging (and of course saves it because of a possible change of apartments in the future), diligently fills out and sends off the guarantee form, reads the abbreviated operating manual, moves on to the full operating manual, makes a couple of phone calls for technical support to clarify things he or she doesn’t feel too sure about; only then does he or she gather up courage to operate the machine. The Israeli colleague, born and raised in the southern part of the eastern Mediterranean basin, rips off the packaging and slams the plug into the electricity socket. It works? Fine. It doesn’t work? Improvise and moan. There are many advantages to both approaches. The truth is probably always in-between. Either way, the smart thing is to find the proper balance between the two ways exaggeratedly depicted here, and to maximize the advantages of each and minimize the disadvantages of each.

The I-TRIZ approach is in principle meant for people of the first variety. Nevertheless, it is a highly powerful tool when placed in the hands of people of the second. In my estimation, Israeli managers, engineers and technicians who have the smallest yearning for and appreciation of the advantages of thinking and systematic work and wisdom will surely learn to admire the power of the system. My belief is that after savoring the taste of success though the method, they too will yield to a certain degree of adaptation to it. If such is the case, the introduction of the I-TRIZ method into Israel may be a starting point for wider and deeper processes of change in the culture of development, production, and operation in organizations that until now have tended to behave according to chance and localized patterns of improvisation and brilliance.